A Step-by-Step Guide to Engine Assembly

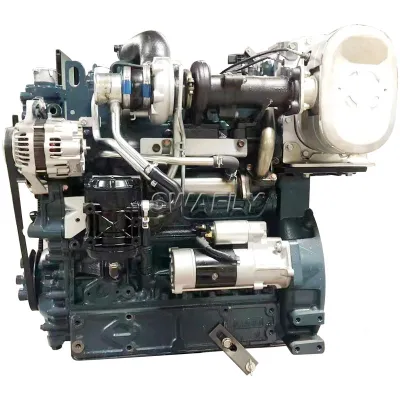

Engine assembly is a crucial process in the manufacture and repair of engines. It involves putting together various engine components, such as the crankshaft, pistons, and cylinder head, to create a functional engine. Engine assembly can be a complex process that requires precision and attention to detail to ensure optimal performance and reliability. In this article, we will provide a step-by-step guide to engine assembly.

Step 1: Engine Block Preparation

The first step in engine assembly is to prepare the engine block. This involves cleaning the engine block thoroughly to remove any dirt, debris, and old gasket material. The engine block should be inspected for cracks, warping, or other damage. If any damage is found, the block should be repaired or replaced before proceeding.

Step 2: Install Camshaft and Timing Components

The next step is to install the camshaft and timing components. This includes installing the timing chain or belt, camshaft sprockets, and tensioner. It is crucial to ensure that the timing is set correctly to prevent engine damage.

Step 3: Install Pistons and Connecting Rods

The next step is to install the pistons and connecting rods. The pistons should be carefully inspected for any damage, such as cracks or scoring. The connecting rods should also be inspected for straightness and damage. It is essential to ensure that the pistons are installed in the correct order and that the connecting rods are torqued to the proper specifications.

Step 4: Install Cylinder Head

The cylinder head is the next component to be installed. The cylinder head should be inspected for cracks, warping, or other damage. The cylinder head gasket should be installed correctly to prevent leaks. It is essential to torque the cylinder head bolts to the proper specifications to ensure a proper seal.

Step 5: Install Intake and Exhaust Manifolds

The intake and exhaust manifolds are then installed. The intake manifold should be torqued to the proper specifications to ensure a proper seal. The exhaust manifold should also be installed correctly and torqued to the proper specifications.

Step 6: Install Valve Train Components

The next step is to install the control valve train components, including the lifters, pushrods, and rocker arms. It is essential to ensure that the valve clearances are set correctly to prevent engine damage.

Step 7: Install Oil Pump and Oil Pan

The oil pump and oil pan are then installed. The oil pump should be inspected for any damage or wear. The oil pan gasket should be installed correctly to prevent leaks.

Step 8: Install Accessories

The final step is to install any accessories, such as the alternator, water pump, and power steering pump. It is essential to ensure that all accessories are installed correctly and torqued to the proper specifications.

Engine assembly is a complex process that requires precision and attention to detail. It is essential to follow the steps outlined above to ensure optimal performance and reliability. If you are not confident in your ability to assemble an engine, it is best to seek the assistance of a professional. By following this step-by-step guide, you can ensure that your diesel engine is assembled correctly and will provide reliable performance for years to come.

More details please visit: www.machineryengine.com

评论

发表评论